Our Clothing and Home supply chain is global and our products are made exclusively for M&S. We don’t own any farms or factories or make the products that are sold in our stores; we source our Clothing and Home products from factories in our key sourcing countries including: Bangladesh, China, Cambodia, India, Pakistan, Sri Lanka, Türkiye and Vietnam. We’re committed to sourcing responsibly and we work closely with our suppliers to ensure they respect human rights, promote decent working conditions, and improve sustainability across our supply base.

We recognise that in complex global supply chains, there will always be challenges, and there will always be more to do. So, we remain committed to monitor the global political, economic and environmental issues and their impact on workers as they emerge. Working closely with our supplier partners, together we will mitigate and remediate as these situations occur.

Click here to see M&S’ business-wide approach to Responsible Sourcing and Human Rights.

Our Approach to Due Diligence

M&S Clothing and Home supplier factories are required to be audited annually by approved independent third party companies and/or the M&S ethical compliance team, against our Global Sourcing Principles and international standards. Factories are expected to implement remediation plans as a result of any audit findings which require improvement.

The ethical audit process, including grading, escalation and audit follow-up activity, is managed by our specialist Sourcing Office compliance teams located in Bangladesh, Cambodia, China, Hong Kong, India, Pakistan, Sri Lanka, Türkiye and Vietnam. Our regional teams also provide a valuable local presence in risk mitigation and remediation activities.

We are also expanding our evaluation of social compliance through assessments and audits further down the supply chain for Clothing and Home products, through M&S ethical site visits and 3rd party audits. This provides us with greater transparency of our Clothing and Home supply base, and a clearer assessment of human rights risks, social performance and labour conditions in our tier 2 facilities.

We expect our supplier partners to communicate with their own suppliers and sub-suppliers involved in producing or supplying Marks & Spencer products or services, and put in place policies and management systems to ensure that they adhere to the Global Sourcing Principles.

We rolled out our tier 2 ethical compliance policy internally in 2024 and began collaborating with our tier 1 suppliers on implementation of the policy and corresponding due diligence requirements. We also carried out a supply chain mapping exercise to improve our visibility of sites in our supply chain.

We’re also working on responsible sourcing of fibres and fabrics further still down the supply chain - click here to learn more about our approach.

At M&S, our social audit programme has been running in our Clothing and Home supply base for over 20 years. We were a founding member of Sedex, which aims to drive improvements and convergence in responsible sourcing practices. The audit programme enables us to monitor compliance with our global sourcing principles, international standards and local law, as well as to identify opportunities for capacity building in our supply base.

Whilst we are confident there continues to be a role for traditional social audit programmes, and we are currently expanding these further down our supply chain, we also recognise their limitations in highlighting certain worker issues. Therefore, in recent years, we have been developing and implementing pilot worker voice programmes to gather more direct worker feedback on their experiences working within our supply chain.

And in 2019, we invited Oxfam to carry out a gap analysis of our supply chains in India and the UK to help us better understand the true worker experience and identify the changes we need to make in our own operations and those of our suppliers. One of Oxfam’s key recommendations was also to scale up our worker voice programmes to help shape a best practice framework for the industry. Since then, we have carried out pilots in over 90 Clothing and Home factories, with a population of over 70,000 workers.

Our key learnings to date are as follows:

- Worker voice provides a hugely valuable mechanism to identify issues which may not typically be found in audits

- Different mechanisms and platforms may be successful in different locations and for different worker demographics

- Programmes should avoid or minimise duplication between brands in shared factories

- Worker engagement and trust that issues will be addressed is key to the success of worker voice programmes, as is factories’ commitment to action to address worker feedback

- Feedback enables implementation of an appropriate mechanism for dialogue and/or grievance between workers and management.

In 2024, based on the learnings from the pilot projects, we introduced a requirement for all tier 1 production sites to have effective worker voice mechanisms in place, and we launched our Global Supply Chain Worker Voice Best Practice Guidelines to support them to do so.

In addition to the primary and secondary data we collect from our supply base, we also regularly refresh our research on key issues in our sourcing countries, to inform our risk assessments and due diligence approach. For example:

- Research into living wages, including academic research, benchmarking exercises of actual wages, cost of living, and desk-based analysis of existing information and field research

- Research into responsible business and implementation of UN Guiding Principles on Business and Human Rights in changing and challenging situational contexts

- Research into the root causes of excessive overtime in garment factories and how to address them

- Our risk identification and prioritisation includes desk-based research, data from our audit programmes, supplier surveys and assessments, and discussions with expert stakeholders through multi-stakeholder initiatives.

Our salient risks are determined at a company level, with input from internal and external stakeholders. For more information on our salient risk assessment process and highest risk locations, please refer to our ESG report and Modern Slavery statement.

Since 2016, we have publicly disclosed our Tier 1 supply base, as part of our commitment to transparency about where our products are made. The map highlights production countries as well as individual factory locations and profiles for sites used by our direct suppliers, as well as additional data points including those relating to worker representation and gender. In 2024, in order to share our data collaboratively and in a standardized manner with others across the industry, we disclosed our tier 1 supply base through Open Supply Hub. Our disclosure includes 100% of our tier 1 production sites and is updated regularly (minimum twice per year). You can view our site data via Open Supply Hub here. In 2024, as part of our ongoing commitment to supply chain transparency, we also signed the Transparency Pledge.

As part of our Global Sourcing Principles, we commit to keep our buying practices under review to ensure that our behaviour supports supplier partners in complying with these Principles. We created our Responsible Purchasing Practices Guidelines to support and educate our colleagues on the importance of responsible purchasing practices. These guidelines are aligned to the Better BuyingTM Five Principles of Responsible PurchasingTM.

We are very proud to hold strong long-term relationships with our clothing suppliers - over 70% have worked with us for more than seven years and these relationships are built on trust and respect. It has always been a priority to respect human rights and to stand up for our workers across our global supply chains. These relationships allow us to honour supplier commitments when supply chain “shocks” occur, as we did, for example, during and after Covid.

We also regularly liaise with our suppliers on purchasing practices and ethical compliance requirements. This includes gathering their feedback through Better BuyingTM, supplier ethical compliance workshops in our sourcing regions, and sourcing summits with suppliers and wider M&S sourcing teams. We also incorporate ethical compliance performance into our supplier performance management scorecard, and increased the weighting of ethical compliance in the scorecard in 2024.

Additionally, in recognition of the role that purchasing practices can play in impacting working hours in the supply base, we have implemented training for internal product-facing teams on the impact of purchasing decisions on factories’ ability to comply with compliance requirements for working hours, and the corresponding impact to workers.

Responsible Factory Exit

We are committed to taking appropriate steps to safeguard the welfare of workers in our supply chain. We are mindful that any decision to shift production elsewhere or close a factory could have negative consequences particularly if such action happens quite abruptly.

The approach to closure and disengagement of factories, which is outlined in our policy, should be planned, with clear rules, policies and commitments based on:

- Compliance – with national laws, international labour standards and the terms of any collective bargaining agreements that are in place

- Consultation between all key internal and external stakeholders

We encourage all parties to work together to mitigate the negative consequences. For example, workers should be paid their legal entitlements including social security, pensions and severance.

We are committed to building a culture of trust and transparency within our business and supply chains and to work with suppliers and business partners to remedy adverse human rights impacts. M&S has a strict anti-retaliation policy. We encourage our employees and individuals within our supply chains and wider communities (including those that represent them) to report any wrongdoing without fear of retribution.

There are a number of ways in which grievances can be raised:

- Supplier partners must provide a grievance mechanism for workers and communities (and their organisations, where they exist) to raise concerns. This grievance mechanism must involve an appropriate level of management and address concerns promptly, using an understandable and transparent process that provides timely feedback to those concerned, without any retaliation against reporters in the form of disciplinary measures or retribution.

- In addition to suppliers' channels, grievances can also be reported through an independent hotline that we support, Safecall. You can read more about this in the M&S Grievance Procedure.

- Allegations and/or grievances relating to our supplier factories and/or more generally to issues in the countries we source from, can be brought to M&S by various stakeholders.

As Ethical Trade is fundamental to the way we do business, we will always investigate any claims which are raised to us and respond to the stakeholder if possible and appropriate to do so. Where necessary, we will seek the support of an independent party to investigate supply chain grievances / allegations. We also remain open to collaborating in shared initiatives which provide access to grievance and remedy in our sourcing locations.

For example, in 2023, we contributed to a research study entitled “Worker and Management Experiences of Workplace Grievance Mechanisms in Cambodia’s Garment Sector”, alongside other brands. In 2024/2025, we began working with Timby both in India (through the South India Garment and Textiles Supply Chain Programme, alongside SAVE) and with all tier 1 factories in Pakistan. We also supported the Mülteci Destek Derneği / Refugee Support Association (MUDEM) Worker Support Centre grievance programme in Turkey.

To see examples of our public responses to stakeholder concerns, click here.

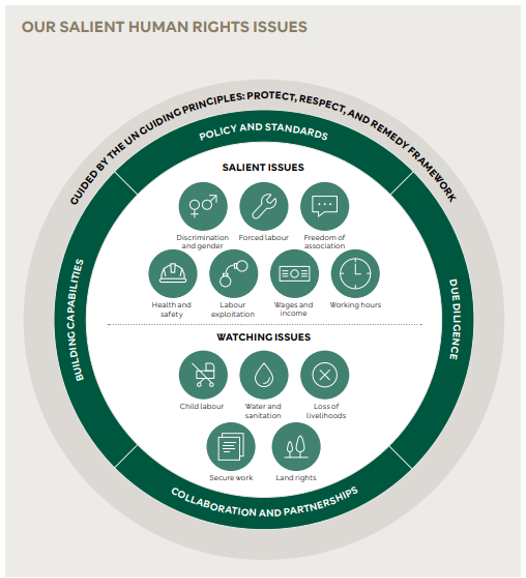

Our Salient Risks and Key Issues

We pair our compliance monitoring and due diligence with worker impact projects to address our salient issues and create positive change for workers. We also collaborate with relevant stakeholders to use our combined influence to maximise that change.

To find out more about our progress within the last year, please see our latest ESG report.

Our Global Sourcing Principles set clear requirements that supply chain partners must provide a healthy, safe and clean workplace for all workers.

As part of our ongoing commitment to working conditions in our supply base, we were a signatory of the original Accord on Fire and Building Safety in Bangladesh (2013), which aimed for sustainable improvements to working conditions in the Bangladesh garment industry. We have since signed the subsequent Transition Accord (2018), the Interim Agreement (2021), the International Accord for Health and Safety in the Textile and Garment Industry (2021, 2023) and the Pakistan Accord on Health and Safety in the Textile and Garment Industry (2023). In 2024, we also joined the Bangladesh Employment Insurance Scheme (EIS), which provides compensation in cases of work-related injuries and is implemented by the ILO and GIZ.

In addition to these commitments, we have also supported many worker impact projects relating to worker health and safety. For example:

- Female worker health programmes with partners including CARE International and RISE.

- Worker commuting safety – e.g. Commuting Safety for Cambodian Workers programme, funded by the US Agency for International Development (USAID)

- Community health programmes e.g. Aider Community Development programme, which focuses on supporting development of workers in the Indian apparel industry and their families, including through free medical camps focusing on eye health and mammography.

Our Global Sourcing Principles outline our requirements for all suppliers on working hours. In order to support compliance with these requirements, we have implemented additional activities beyond our monitoring programme.

For example, we commissioned research in China on root causes of excessive working hours, and a subsequent supplier guidance document will be shared with other suppliers.

Additionally, in recognition of the role that purchasing practices play in impacting working hours in the supply base, we implemented training for internal product-facing teams which includes the impact of purchasing decisions on factories’ ability to comply with compliance requirements for working hours, and the corresponding impact to workers. We also are engaging with our suppliers as participants of Better Buying™ to gather feedback on the impact of our purchasing practices.

All workers are entitled to fair and equal compensation that at least meets the legal minimum wage, industry standards, or negotiated wages. Contracts, wages and benefits are among the most important conditions of work.

While M&S does not own any factories, nor pay workers directly, and our suppliers have many other customers, we recognise the importance of using our influence to improve workers’ financial situation. To date, we have:

- Wage compliance monitoring – through our compliance programme, verifying that workers are paid correctly, on time, and in line with their skill level

- Ensuring our responsible purchasing practices support wage compliance

- Implemented programmes supporting freedom of association

- Completed wage digitisation programmes in supplier factories – in partnership with Mastercard Centre for Inclusive Growth and Better Than Cash Alliance, to improve payment accuracy, increase workers’ ability to save and improve financial inclusion

- Continue to roll out financial literacy training for factories (e.g. RISE Financial Health, which supports workers, especially women, to access, use and benefit from financial products and services and build their financial capability to improve their financial health and resilience).

We are committed to inclusion and diversity and believe everyone should feel comfortable to come to work and be themselves. We have a zero-tolerance stance on discrimination, harassment and unacceptable behaviour.

Whilst gender-related issues and discrimination can be difficult to identify through social compliance audits, we use our grievance mechanisms to identify issues wherever possible, and we use worker impact projects to proactively address gender and discrimination-related risks. These include:

- Marks and Start, which aims to support people who face barriers to employment, offering training and opportunities for inclusion into work. Marks and Start began in 2004, and has successfully supported more than 29,000 people around the world, offering skills and training that lead to the opportunity of a job.

- Gender Equality and Returns (GEAR) is an initiative of Better Work, which aims to promote women’s career progression opportunities by equipping them with technical, managerial and leadership skills. M&S has supported this project for factories in Sri Lanka and Bangladesh.

- Providing Opportunities to Women for Equal Rights (POWER) - since 2016, we’ve worked in partnership with the British High Commission and Change Alliance programmes in India to promote gender equality, providing training to over 13,500 workers. The programme provides female workers with training across gender balance awareness, technical skills, and financial and digital literacy to address root causes of gender inequality at work and in the community.

- Apparel Training and Design Centre (ATDC) Vision Of Individual Career Evolution (VOICE) – which aims to facilitate women’s empowerment through career progression and capacity building for existing supervisors in India.

- Mothers@Work, a national initiative to strengthen maternity rights and protect breastfeeding support in the workplace for young working mothers in Bangladesh, lead by UNICEF among other stakeholders.

- Shojag (Awaken) Coalition programme, aiming to reduce gender-based violence in the garment (RMG) industry in Bangladesh.

We aim to ensure that everyone in our supply chain has a voice and encourage a culture of open dialogue and continuous improvement between workers and management. Freedom of association, i.e. the right of workers and employers to form and join organisations of their own choosing, is an integral part of a free and open society. M&S respects the workers’ rights to freedom of association.

We promote workplace representation by:

- Participating in initiatives which provide capacity building to factories on Freedom of Association e.g. ILO Better Work and ETI Social Dialogue programme

- Verifying worker representation during our ethical compliance monitoring programme

- Engaging with external stakeholders, including unions, on a case-by-case basis if allegations/issues are raised relating to freedom of association, to resolve issues with the factory

- Including information on our interactive map, for transparency where suppliers have a worker committee and/or trade union

We recognise that modern slavery is a growing global issue, and we understand our responsibility to prevent, mitigate and remediate in accordance with the responsibility to respect human rights under the UNGPs. Our colleagues and supply chain partners play a key role in helping us to achieve this. Our Modern Slavery Statement sets out our approach to preventing slavery and human trafficking in our operations and supply chains.

Vulnerable groups such as but not limited to women, the youth, migrants, ethnic minorities, the elderly, indigenous peoples, can be disproportionately impacted by negative human rights abuses. Supplier partners must carry out risk assessment as part of their due diligence to ensure heightened protection, and remedy for these vulnerable groups

“Who made my clothes” is a question increasingly asked by consumers, especially after the spate of serious industrial accidents in the past. Of the many millions of workers engaged in global supply chains, those in the lowest tiers are often not visible to the brands they produce for and are certainly not visible to end consumers because they work in off-site facilities in their homes, public spaces outside of their homes or small workshops close to their homes.

Historically, the lack of visibility of homeworkers in supply chains, combined with their complicated employment status in many countries, has made them a vulnerable group of workers. Many homeworkers have been underpaid and sometime unsafe. We believe that one of the first steps towards reducing the vulnerability of these workers is to take an open and positive position towards homeworking.

Our Homeworking Policy outlines the conditions under which we will accept homeworking, and our requirements for due diligence to ensure these workers are treated fairly – we will continue to work on implementation of this policy for what is a complex issue.

Unauthorised subcontracting presents a risk to workers, as without visibility, ethical compliance standards cannot be verified. Therefore, we don’t accept production from unapproved sites. Our internal supplier partner subcontracting policy outlines our requirements.

Our Global Sourcing Principles require supplier partners, where applicable, to ensure that facilities for workers are clean and safe and meet their needs. Workers’ accommodation arrangements must not restrict workers’ freedom of movement or of association, and must be consistent with the principles of non-discrimination and equal opportunity.

On-site worker accommodation is included in our compliance monitoring, and we also continue to share industry guidance with our suppliers, such as the ILO Workers’ Housing guidance.

Alongside tackling climate change from an environmental point of view, we are beginning to assess the links between the climate crisis and the human rights impacts on the workers in our supply chain.

Just Transition should be as fair and inclusive as possible to everyone concerned, creating decent work opportunities, ensuring gender equality, reducing negative impact on workers and ensuring the human rights for the most vulnerable workers are respected and upheld.

As such we will be contributing to a RISE research programme entitled “Defining a gender-just and equitable response to climate change within the garment industry” and we are participating in the ETI’s Just Transition working group.

You can also read more about our approach to circularity and sustainability here.

Our Policies and Standards

To supplement our Global Sourcing Principles, and help our Clothing and Home suppliers meet our requirements and improve their working conditions, a number of supporting policies, procedures, guidelines and tools are available.

You can read more about some of these here: M&S Human Rights Policy, M&S Child Labour Procedure, M&S Grievance Procedure for Clothing, Home and Food Supply Chains, M&S Forced Labour Toolkit For International Suppliers and Partners, Responsible Factory Exit And / Or Closure Guidelines, Sandblasting Policy, Responsible Purchasing Practices Guidelines, Global Supply Chain Worker Voice Best Practice Guidelines, and Homeworkers Policy.

Whilst we are predominantly an own-brand retailer; licensed and non-M&S branded goods are a growing proportion of what we sell. Suppliers of non-M&S branded goods are expected to have noted the requirements of our Global Sourcing Principles and to have established similar arrangements.

We are committed to taking appropriate steps to safeguard the welfare of workers in our supply chain. We are mindful that any decision to shift production elsewhere or close a factory could have negative consequences particularly if such action happens quite abruptly.

The approach to closure and disengagement of factories should be planned, with clear rules, policies and commitments based on:

- Compliance – with national laws, international labour standards and the terms of any collective bargaining agreements that are in place

- Consultation between all key internal and external stakeholders

We encourage all parties to work together to mitigate the negative consequences. For example, workers should be paid their legal entitlements including social security, pensions and severance.

Our Programmes

Whilst compliance monitoring and audits play an important role in verifying suppliers are meeting M&S requirements, we also recognise the need to develop a continual improvement culture in our supply base, and to address root causes and spark systemic change.

We therefore complement our existing activities by going ‘beyond compliance’ and defining areas of continuous improvement with our suppliers. We do this by providing a range of capacity building tools and training.

We have included just a few examples below; you can view more in the Programmes Archive or our latest sustainability report.

In Turkey we implemented a women’s empowerment pilot programme in nine factories with a total worker population of almost 6,000 workers. This three-stage programme includes: gender gap analysis using the UN Global Compact Women’s Empowerment Principles Gender Gap Analysis Tool, employee surveys on perception of gender equality and working environment, and gender equality training.

Read more about our current programmes in our 2024 Sustainability Report.

In response to the Covid-19 health impacts on workers and communities in Bangladesh, we worked with CARE International on a project to address low vaccine uptake by urban marginalised populations. Together, we set out to ensure all 100,000 workers in 34 factories in Gazipur had access to the vaccine. CARE ran awareness training and provided electronic registration and vaccination certificates for the workers.

Read more in our 2024 Sustainability Report.

Our International Marks & Start programme began in 2004. Its aim is to reduce discrimination and provide employment, and in early 2022 a new Marks & Start programme was launched, which aims to establish a Centre of Excellence for the Apparel Industry in Sri Lanka. It supports those with disabilities, or those in other marginalised groups, to access employment.

At M&S, our social audit programme has been running in our Clothing and Home supply base for over 20 years. We were a founding member of Sedex, which aims to drive improvements and convergence in responsible sourcing practices. The audit programme enables us to monitor compliance with our global sourcing principles, international standards and local law, as well as to identify opportunities for capacity building in our supply base.

Whilst we are confident there continues to be a role for traditional social audit programmes, and we are currently expanding these further down our supply chain, we also recognise their limitations in highlighting certain worker issues. Therefore, over the last couple of years, we have been developing and implementing pilot worker voice programmes to gather more direct worker feedback on their experiences working within our supply chain.

And in 2019, we invited Oxfam to carry out a gap analysis of our supply chains in India and the UK to help us better understand the true worker experience and identify the changes we need to make in our own operations and those of our suppliers. One of Oxfam’s key recommendations was also to scale up our worker voice programmes to help shape a best practice framework for the industry. Since then, we have carried out pilots in over 90 Clothing and Home factories, with a population of over 70,000 workers.

Our key learnings to date are as follows:

- Worker voice provides a hugely valuable mechanism to identify issues which may not typically be found in audits

- Different mechanisms and platforms may be successful in different locations and for different worker demographics

- Programmes should avoid and minimise duplication between brands in shared factories

- Worker engagement and trust that issues will be addressed is key to the success of worker voice programmes, as is factories’ commitment to action to address worker feedback

- Feedback enables implementation of an appropriate mechanism for dialogue and/or grievance between workers and management.

In 2024, based on the above learnings, we created Global Supply Chain Worker Voice Best Practice Guidelines.

HEALTH PROGRAMMES

Targeting women garment workers and their communities, our health projects have delivered immediate and midterm interventions, to support and re-stabilise community health care systems and services, deliver targeted health messaging and communications in and around factories, and build community-level capacity for collective action. The projects complement workplace safety guidelines already being implemented in factories and a result of these interventions, the garment supply chain benefits from safer working conditions, reduced absenteeism and improved productivity.

The projects strengthen the functionality of public-private healthcare networks to maintain crucial services and improve linkages between facilities and factories for reduced long-term health consequences. Women garment workers are supported to become community leaders to mobilise WASH interventions benefiting themselves, their families and communities.

We have run these projects in Cambodia and Bangladesh, with lighter versions in India, Sri Lanka and China.

HEALTHWORKS

Another example is where we developed HealthWorks with Project Hope and the Reproductive Health Association of Cambodia (RHAC) to address simple root causes of absenteeism, and fatigue and increase health and nutritional awareness in 7 factories in Cambodia. We trained over 14,000 workers and upskilled the medical professionals on site to help improve employee health as well as workplace productivity.

FCDO VSCF

We also participated in several projects in the Foreign and Commonwealth Development Office Covid-19 Vulnerable Supply Chains Facility (VSCF) fund in Bangladesh. VSCF aimed to form partnerships with businesses and NGOs rapidly, to respond to the financial challenges from Covid-19 and help with longer-term resilience. In one VSCF project, M&S partnered with CARE to address the health impacts of the pandemic on 80,000 garment workers and their communities. Working across 15 communities, the project strengthened urban primary healthcare systems by maintaining health clinics, providing support for Covid-19 testing and quarantining, setting up digital wellbeing centres, training local health “champions”, and educating factory workers and management on risks of sexual harassment and violence to women. The results showed that 98% of all factory staff surveyed reported a safer working environment. In addition, they saw an increase in health and hygiene measures by factory workers, and the delivery of guidance combatting gender-based violence to 73,000 workers in 25 factories.

WAGE DIGITISATION PROGRAMMES

Opening bank accounts for those who were previously unbanked and processing direct transfer of salaries to bank accounts for low-income factory workers using biometrics such as fingerprints rather than documentation has had a direct, positive, wage-related impact for the worker in many ways:

- Living wage increase through reduction of leakage and corruption associated with cash salary payments;

- Security of cash

- Income on their cash

- Social inclusion

- Becoming part of the formal economy

- Financial security and control leads to a desire to further improve education and promotion opportunities in workers

WORKPLACE COMMUNICATIONS PROGRAMME

Effective workplace engagement is key to achieving a healthy workplace environment. It is important to start by building trust through efforts to improve information provision and consultation with workers.

To help our suppliers in this task, we developed a Workplace Communications programme - a two day training course and toolkit available for all our suppliers, which set out how to develop or improve the provision of, and management interaction with, trade unions, worker committees, effective communication channels and trade union relationships.

FACTORY SAFETY PROGRAMMES

For several years from 2012 we implemented a Fire Safety programme in all factories in Bangladesh with Worldwide Responsible Accreditation Production (WRAP). The programme was unique to M&S due to its fire champion module which takes workers right through from how fires start, the context and risks within the workplace, to how to effectively evacuate the workplace, the importance of safe practices and how they play a part in reducing the risk of fire in the workplace and their homes. By December 2015, all of our garment factories had a worker fire champion in place. This training is now carried out with the International Accord.

LEADERSHIP AND PERSONAL DEVELOPMENT PROGRAMMES

We worked with Emerging Leaders, an NGO that provided leadership training to around 50,000 supply chain workers in Kenya, east Africa and South Africa, India, Sri Lanka and Bangladesh. The training takes participants on an incredible journey to a new mind-set and empowers them to take others on the same journey as leaders in their communities. Many tell us that the programme has led to improved productivity, better retention of high quality, motivated employees and less dependency on casual labour.

Between April 2019 and March 2020, we directly helped 4,704 people in our supply chains through our partnership with the Emerging Leaders training programme (last year: 15,000). In addition, an estimated 56,875 people have benefited indirectly according to the Emerging Leaders multiplier methodology. (https://marksandspencer.sid2-e1.investis.com/sites/marksandspencer/files/press_release/2020/plan-a-report-2020.pdf)

GENDER EMPOWERMENT PROGRAMMES

Since 2016, we’ve worked in partnership with the British High Commission and Change Alliance programmes in India to promote gender equality and ensure safe environments for female workers. The POWER programme (Providing Opportunities to Women for Equal Rights) encourages women to join and lead the labour market, and comprises three pillars: gender equality (addressing stereotypes), accountability (creating a mechanism for complaints to be heard), and responsiveness (creating a culture that enables women to speak up).

Key initiatives include helping female workers build communication skills, manage their money, maintain good health, and plan for the future. Starting in 2022, the second phase of POWER helps women build on the work done so far, taking on new responsibilities at work and leadership roles, both in and out of the factory. The programme offers training in gender and life skills, and identifies technical skills required for progression. The first cohort includes 16 manufacturing units, 16 peer trainers and 1,700 workers.

Collaboration and Partnerships

We’re very proud to have strong, long-term relationships with our clothing suppliers - over 70% have worked with us for more than seven years and these relationships are built on trust and respect. We are also using Better BuyingTM to gather feedback from our suppliers on the impact of our purchasing practices.

We know that who makes their clothes and where is important to our customers, so we were the first major retailer to list all our factories on our interactive supplier map, from which we have since switched to use Open Supply Hub, and we update this at least twice per year.

Listening, learning, responding and working in partnership is an important part of how we do business. We’re working with a large number of organisations to support our responsible sourcing activities. We were founding members of the Supplier Ethical Data Exchange (Sedex), which aims to drive improvements and convergence in responsible sourcing practices. We support a number of programmes that help improve working conditions in our supply base, in partnership with organisations such as Better Factories Cambodia and ILO Better Work (since 2007).

We were also a signatory of the original Accord on Fire and Building Safety in Bangladesh (2013) which aims aimed for sustainable improvements to working conditions in the Bangladesh garment industry. We have since signed the subsequent Transition Accord (2018), the Interim Agreement (2021), the International Accord for Health and Safety in the Textile and Garment Industry (2021, 2023) and the Pakistan Accord on Health and Safety in the Textile and Garment Industry (2023). In 2024/2025, we joined the Bangladesh Employment Insurance Scheme (EIS), implemented by the ILO and GIZ, which provides compensation in cases of work-related injuries. We were also one of the first companies to formally sign the Call to Action on human rights abuses in the Xinjiang region: Brand Commitment to Exit the Uyghur Region. Working in collaboration with other stakeholders is a key part of our work to drive improvements across the industry. We do this through our participation in groups including the Ethical Trading Initiative, RISE, the South India Garment and Textiles Supply Chain Project and the India Brands Ethical Working Group, among others.

Read our responses to stakeholder concerns here, including Covid-19.

| DATE | TITLE | DOWNLOADS |

|---|---|---|

| Sep 2023 | Responding to Stakeholder Concerns | |

| July 2023 | Response to Transform Trade petition | |

| Jan 2023 | Global Sourcing Principles | |

| Aug 2022 | Responding to Stakeholder Concerns | |

| Aug 2022 | Ethical Audits Methodology - C&H | |

| Aug 2022 | Ethical Audits Data - C&H | |

| Sept 2020 | Covid 19 PDF | |

| Nov 2016 | M&S Child Labour Procedure |